We just visited with a customer who told us, ever since they started die cutting and back-slitting their labels, their customers aren’t shopping them anymore.

What are the benefits of Back-Slitting?

Back-slitting is also known as “crack and peel” to some buyers in the industry. With the Gerber Edge and enVision 375 cutter, this process is made easy, and increased savings from production time, in comparison to other digital processes are just two of many benefits. If you are going to die cut, you might as well back slit to aid in the application. The real benefit is the profit from going where the others aren’t. The Gerber enVision using Gerber Omega software truly shines in this area.

To break my introductory paragraph into a bit more detail, let me start with the result… Their customers aren’t shopping them anymore. Ask yourself, what will it mean to you if what you produce can’t be easily produced by your competitor. Do you skew your sales pitch and product line according to the rules of supply and demand? Lazy thinking in this area will produce lazy profits.

To break my introductory paragraph into a bit more detail, let me start with the result… Their customers aren’t shopping them anymore. Ask yourself, what will it mean to you if what you produce can’t be easily produced by your competitor. Do you skew your sales pitch and product line according to the rules of supply and demand? Lazy thinking in this area will produce lazy profits.

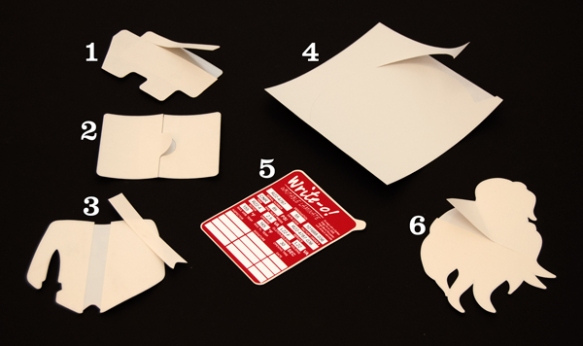

We numbered and then flipped these labels over (below) to show the variety of back slits.

We numbered and then flipped these labels over (below) to show the variety of back slits.

- This data plate has label placement tabs that allow the production line applicator to position the label quickly and consistently every time. They just peel the bottom off, place it, press down where the adhesive is exposed, then remove the backing and press the rest of the label down. To see it in action, click here.

- This reflective label has a thumb tab the pops up when you bend the label.

- This is a miniature sample of a front number plate on a motocross bike. It has a double back cut so that the user can remove it and then position the Convex High-Bond accurately before peeling the two sides off. You can position the back slits where you want. In this case it aids in burnishing from the center out.

- This glow-in-the-dark label is back slit in to follow the shape of the moon. Again, this illustrates that any shape you can cut on the face, can also be cut on the liner.

- This label is not slit across the back, but has a thumb tab sticking out at the top right corner to aid in peeling the liner off. It’s those little touches that keep customers coming back.

- This is a simple single back slit on a fairly intricate helmet decal. Stacking decals like this, and even shrink wrapping them makes a good impression.

If you need help understanding how to back slit or die cut, please don’t hesitate to call us at 800-232-8018. This process will help you get more involved with your customers. The better your customer feels that you understand their business, the better it is for you – it builds trust.

If you need help understanding how to back slit or die cut, please don’t hesitate to call us at 800-232-8018. This process will help you get more involved with your customers. The better your customer feels that you understand their business, the better it is for you – it builds trust.

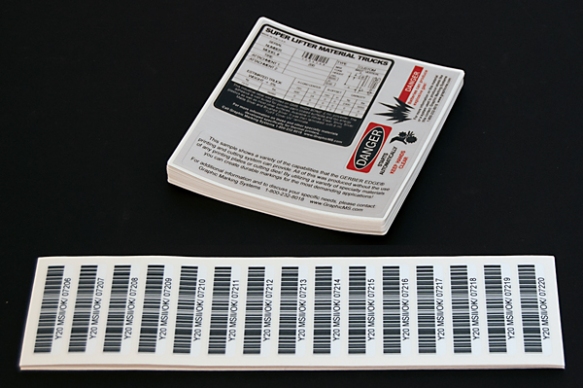

The picture above shows a “label kit” and sheets of labels. The Gerber enVision can be used for producing such kits, sheets, and even rolls of labels.

The picture above shows a “label kit” and sheets of labels. The Gerber enVision can be used for producing such kits, sheets, and even rolls of labels.